What is the function of a diesel engine?

A diesel engine system is an internal combustion engine that operates on diesel fuel. It is a widely used technology for powering various vehicles, industrial equipment, and generators. The system includes several key components that combine to convert the chemical energy stored in diesel fuel into mechanical energy, which can be used to perform work.

Diesel engines are diesel-fueled engines used in relatively large vehicles because they can produce a large force at low speeds. Also, because fuel economy is good and fuel price is low, it is becoming popular in passenger cars because it is economical. Even in a car with a diesel engine, the parts except the engine (clutch, transmission, differential, etc.) have almost the same configuration as gasoline engine vehicles. ( Diesel engine diagram )

What is the difference between a diesel and a gasoline engine?

Diesel and gasoline engines are like two types of engines that make cars and machines go. Diesel engines use a heavy fuel called diesel and don’t need a spark plug to start; they work by squishing air hard until it’s so hot that it makes the fuel ignite by itself. Diesel engines are good for big trucks and heavy-duty jobs because they have lots of power at low speeds.

Gasoline engines use a lighter fuel called gasoline and need a spark plug to start. They are better for smaller cars and where you need to go fast because they have more power at high speeds. Each type has its own strengths, like diesel engines being good for pulling heavy things, and gasoline engines being good for zipping around quickly.

how does a diesel engine work

Self-ignition of fuel (diesel engine)

In diesel engines and gasoline engines, the way fuel burns is quite different. The gasoline engine ignites the air-fuel mixture with a spark of a spark plug. We call this “spark ignition”. Just the same principle as igniting a lighter.

Diesel engines are burning with fire by injecting fuel into places that have high temperatures to compress the air. We call this “self-ignition”. When we put cooking oil on a pan on the stove, once the temperature of the cooking oil rises, the cooking oil gets fired and burned. Self-ignition is just like this mechanism.

Diesel engine diagram

The flow of the Diesel engine each stroke

How does the diesel engine burn fuel and create power?

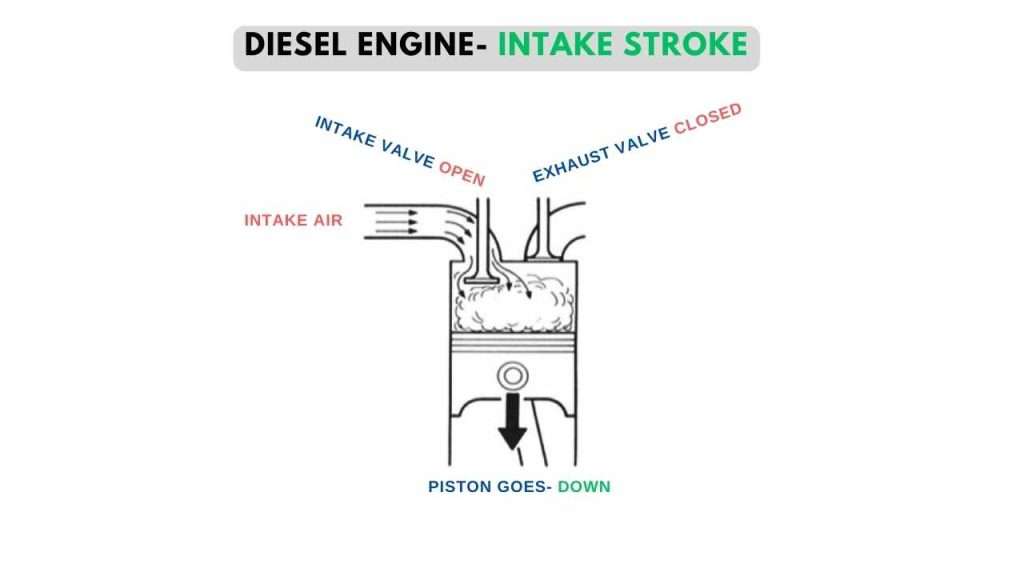

Diesel engine Intake stroke diagram

The basic structure of a diesel engine is almost the same as that of a gasoline engine. The engine body consists of a piston, a valve mechanism, a crankshaft, a cylinder block, and so on. At the time of intake,

1) the piston goes down with the intake valve open,

2) the air cleaner removes dust, and

3) the air is sucked into the cylinder. At this time, the diesel engine sucks only the air unlike the gasoline engine sucking the air-fuel mixture.

When putting air into the tire of a bicycle, the surface of the pump is hot because the air is compressed and heat is generated.

In the diesel engine, it compresses the air and generates the heat necessary for diesel ignition. However, if the amount of intake air is small, the heat necessary for ignition does not occur even if it is compressed, so it is necessary to suck as much air as possible. For this reason, the diesel engine does not have a throttle valve that hinders intake.

In a diesel engine during the intake stroke, there are some important components that help bring in the air needed for combustion. Let’s break down a few of them:

Air Temperature Sensor:

This is like a little detective that checks how hot or cold the air is. It helps the engine know if the air needs a bit of warming up or if it’s already good to go. ( learn Basic Car Brake Systems )

Intake Air Filter:

Imagine this as the engine’s nose. It filters the air before it goes inside, making sure it’s clean and doesn’t have any dirt or dust. Just like you wouldn’t want to breathe in dusty air, the engine prefers clean air too!

Throttle Valve:

Think of the throttle valve as a gatekeeper. It controls how much air can go into the engine. If you press the gas pedal in your car, the throttle valve opens up, letting in more air. If you ease off the pedal, it closes a bit to reduce the air.

During the intake stroke, what are the positions of the valves?

When the engine takes a breath, called the “intake stroke,” there are valves inside it that act like doors. One valve, called the intake valve, opens up to let air come into the engine. Think of it as the engine breathing in. The other valve, called the exhaust valve, stays closed during this time. So, during the intake stroke, the intake valve is like an open door, letting fresh air inside, and the exhaust valve is like a closed door, keeping the used-up air and gases from getting out. This helps the engine get the right amount of clean air it needs to mix with fuel and run properly.

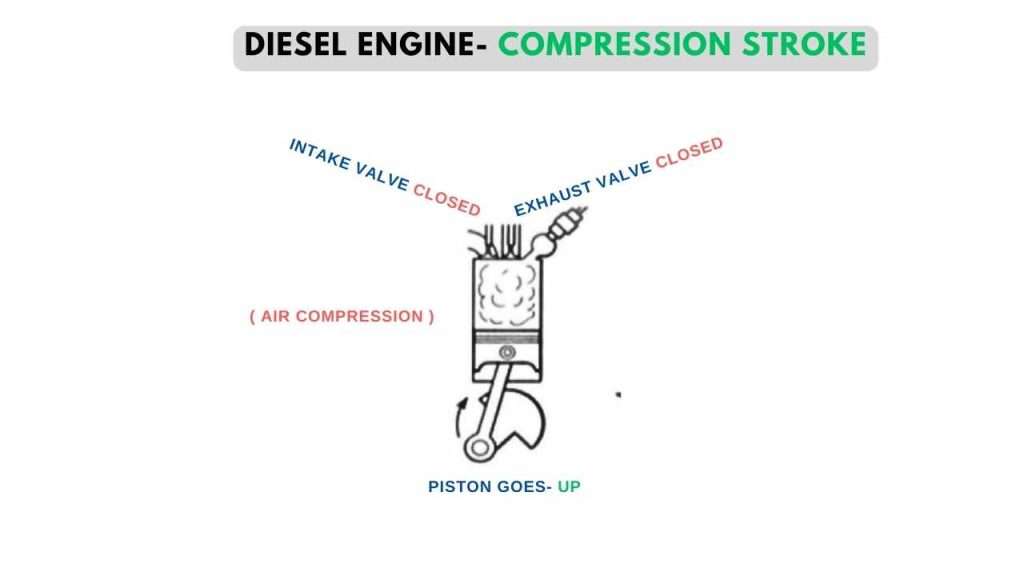

Compression stroke tdc

Diesel engine Compressing stroke compresses air to generate heat.

When the piston rises with both the intake valve and the exhaust valve closed, the air sucked in the previous stroke is compressed. This compression raises the temperature of air and brings it to the temperature where fuel can be ignited.

Since the air must be compressed until the fuel reaches a high temperature to ignite, the compression ratio of the diesel engine is set at about 15 to 22. This is a very high compression ratio compared to the compression ratio of gasoline engines (around 8 to 11). Also, high compressing generates a large force at the time of burning, it has powerful characteristics even at low speed, and it can be said that it is suitable for the use of buses and trucks.

The diesel engine has a small combustion chamber in order to obtain a high compression ratio, and the gap between the top of the piston and the valve when the piston is at the top dead center is very narrow. Also, as the piston and other parts require strength enough to withstand this high compression, the engine itself is heavier than the gasoline engine.

during the compression stroke, what is the position of the intake valve?

During the compression stroke in an engine, which is like the “squeezing” phase, the intake valve is in a closed position. In simple terms, it acts like a shut door. Unlike the intake stroke where the intake valve allows air to enter, during compression, the intake valve stays closed. This closure is important because it traps the air that was brought in during the intake stroke inside the engine cylinder. By closing the intake valve, the engine can compress or squeeze the air tightly, preparing it for the next step, which is the ignition of fuel to create power. So, during the compression stroke, the intake valve is firmly closed, allowing the engine to build up the pressure needed for efficient combustion.

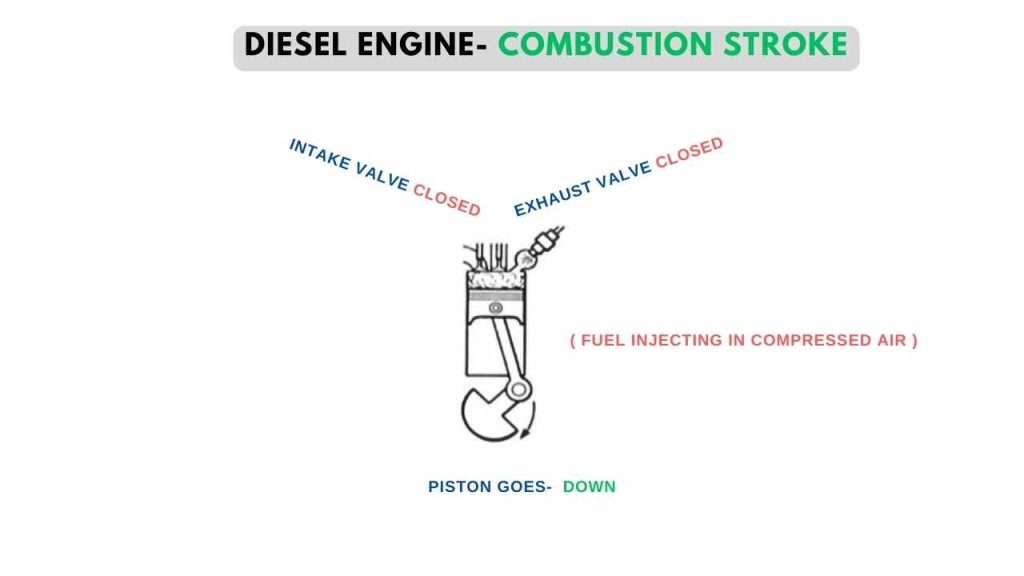

What is a combustion stroke

Combustion stroke of a diesel engine: injection of fuel and combustion

Fuel is injected at higher pressure into the air of the compressed and high temperature and high-pressure combustion chamber. Then, the fuel is self-ignited by exposure to high temperature air, and combustion begins. This burning pressure pushes the piston down and becomes the power to move the car. In a diesel engine, since a predetermined amount of fuel has to be injected into a combustion chamber in which air is compressed to a high pressure, special equipment for sending fuel is not required for the gasoline engine.

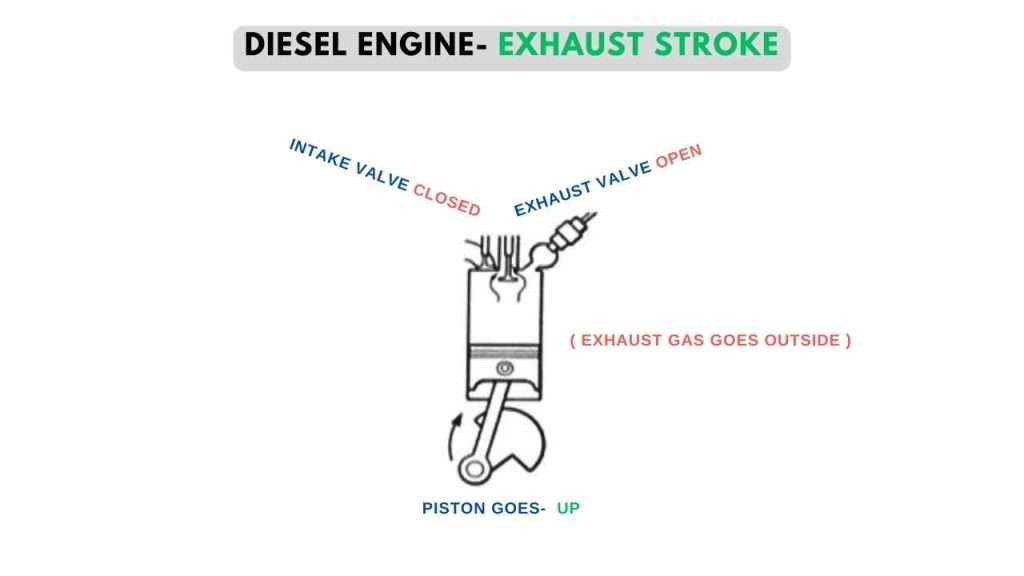

Exhaust stroke definition

Diesel engine exhaust stroke Discharges combustion gas.

During the exhaust stroke of a diesel engine, the piston moves upward with the exhaust valve open, facilitating the expulsion of combustion gases from the cylinder. This phase is similar to the exhaust stroke in a gasoline engine. As the piston ascends, it pushes the spent combustion gases out of the cylinder and into the exhaust system. The exhaust valve remains open during this stroke to allow for the efficient discharge of the burned gases. Once the majority of the exhaust gases have been expelled, the exhaust valve closes as the piston reaches the top of its stroke, preparing the cylinder for the subsequent intake of fresh air during the next cycle. This continual process of intake, compression, power, and exhaust strokes forms the fundamental operation of a four-stroke diesel engine, powering various applications such as vehicles, industrial machinery, and generators.

How to tell the difference between compression and exhaust stroke

Imagine your car’s engine is like a giant pump, moving up and down to make everything work. When the engine breathes in air and fuel, it’s called the compression stroke. It’s like the engine taking a deep breath to get ready for action. During this time, the piston inside the engine moves up, squeezing the air and fuel together. Now, when the engine breathes out, it’s called the exhaust stroke. It’s like the engine letting out a big exhale. In this stroke, the piston still moves up, but this time the exhaust valve opens, allowing the used-up gases to leave the engine. So, to tell the difference, if the engine is taking a breath (compression), both valves are closed, and if it’s letting out a breath (exhaust), the exhaust valve is open. That’s how the engine keeps pumping and working smoothly! ( learn more )

Compression Stroke:

-Piston moves up from bottom to top.

-Both intake and exhaust valves are closed.

-The engine takes a deep breath, squeezing air and fuel.

Exhaust Stroke:

-The piston moves up again, but the exhaust valve is open.

-Only the exhaust valve allows used-up gases to leave.

-The engine lets out a big exhale, getting rid of old gases.

How many intake and exhaust valves are there in a two-stroke cycle engine?

In a two-stroke engine, there is usually just one intake valve and one exhaust valve. This is different from engines with more strokes, which have separate valves for different tasks. The two-stroke engine is simpler, doing everything in just two movements of the piston—up and down. So, it has one valve to let in the air and fuel (intake valve) and another to let out the used-up gases (exhaust valve). This makes two-stroke engines compact and easy, commonly used in things like small motorcycles and power tools.

( 2nd part of advanced diesel engine diagram)